Chlorine-free technology

for healthy poolsFor more than 25 years, we’ve been helping our customers to enjoy a healthy swimming pool. We are an innovative and technological company from the heart of Europe. We have been helping our customers swim in a healthy pool for over 25 years. Nature is our greatest mentor. We harness its natural power inside our products for the most effective water Treatment today’s technology can offer.

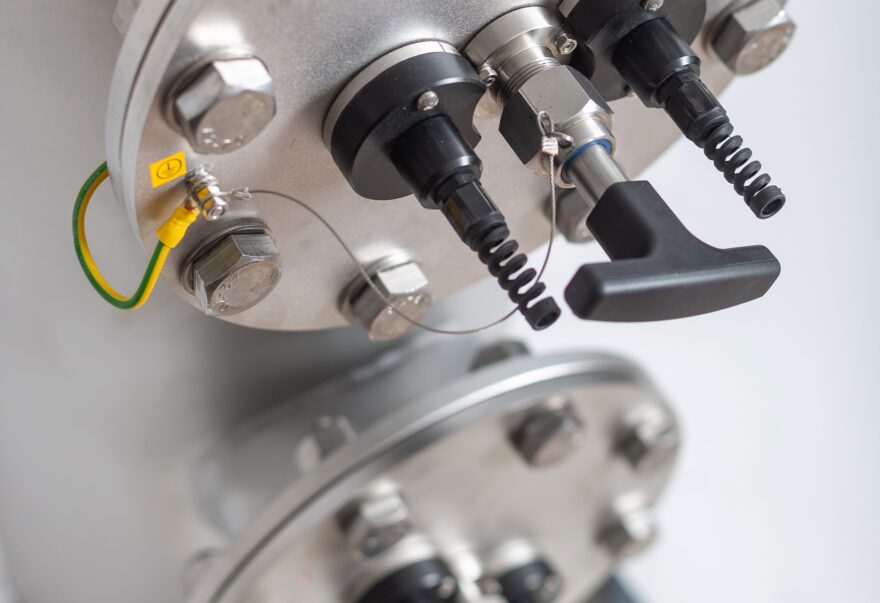

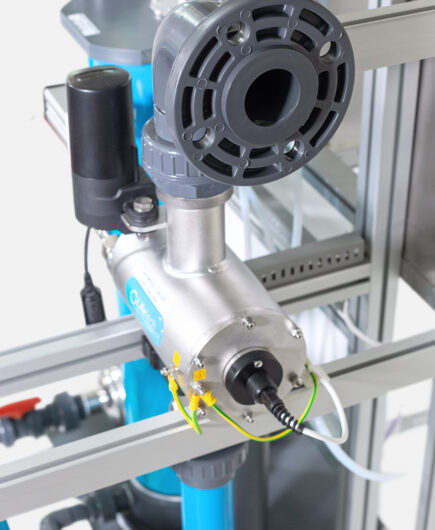

A pool equipped with our technology isn’t just healthier; it is also up to 40% cheaper to maintain. To accomplish this mission, we design, develop, and manufacture the technology of ozone, UV, and their combination AOP. We train our distributors and partners to install, and reliably maintain these solutions. The synergy of UV and ozone represents the latest and most efficient water disinfection technology available. This new and highly efficient technology is known as AOP, or Advanced Oxidation Process. You can find our technology in thousands of residential pools, hundreds of hotel pools, and dozens of water parks worldwide.

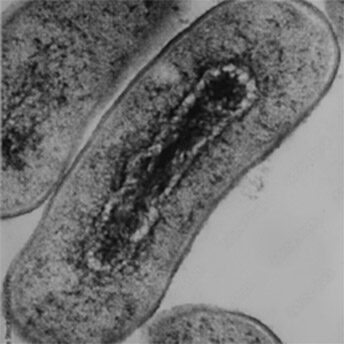

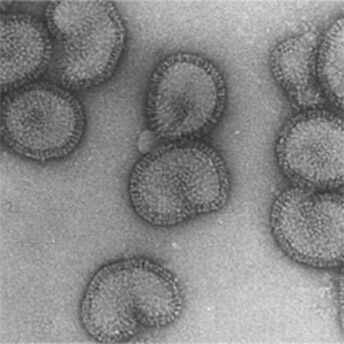

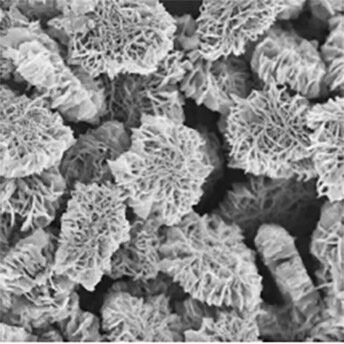

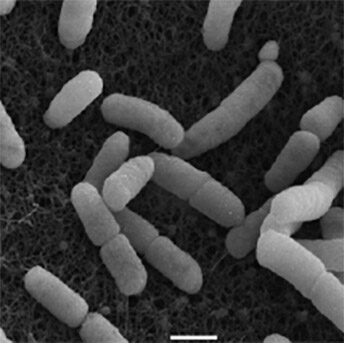

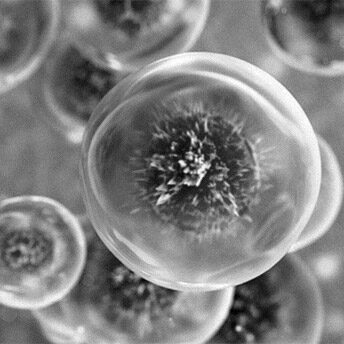

Water disinfection is a fundamental aspect for a sustainable solution for swimming pool water. Just because we don't see the problem right away, doesn't mean it isn't in the water. Take a close look

Lifetech’s advanced water treatment technologies have redefined swimming pools by introducing the concept of a “healthy pool“—a pool free of harmful trichloramine, with reduced chlorine levels, improved air quality, and safer conditions for swimmers, including toddlers and allergy sufferers.

Their medium-pressure UV systems are installed in over 3,400 pools worldwide, including luxury resorts like TA’AKTANA in Indonesia and public facilities such as AquaDream Aquapark Barrandov in Prague. In Norway’s Skjaak Swimming Pool, Lifetech’s technology reduced free chlorine levels by 70%, meeting the highest standards of a healthy pool. More references

Why work with us?

Lifetech offers complete collaboration, providing expert training, reliable spare parts, and ongoing technical support. Their innovative solutions minimize chemical usage, lower operating costs, and ensure exceptional water quality for both private and public pools. Read more about us

News

Why is Lifetech’s unique technology LifeOX® M the best available technology for pool treatment

Technology

LifeOX® technology provides the highest possible oxidation potential within AOP

Technology

Swimming pools and their health risks: what is not talked about and how to prevent the risks

Healthy pool

LifeAGE® technology sharply reduces the operating costs of medium-pressure UV systems

TechnologyReferences

Sheybarah Island – Red Sea Global, Kingdom of Saudi Arabia

Public pools, Private pools AOP (advanced oxidation process)

Lifetech technology in the Skjaak Swimming Pool – Norway

Public pools AOP (advanced oxidation process)

TA’AKTANA, a Luxury Collection Resort & Spa, Labuan Bajo, Indonesia

Public pools, Public whirlpools AOP (advanced oxidation process)Lifetech industry

Lifetech offers cutting-edge water disinfection technologies across a wide range of industries. Lifetech solutions are perfect for disinfecting drinking water, wastewater, supporting applications in industrial processes, the food and beverage sector, aquaculture, as well as for cleaning cooling emulsions and cutting fluids.

With over 30 years of experience, innovative development, and patented technologies such as LifeOX-M and LifeAGE®, we help our partners enhance cleaning efficiency, reduce costs, and gain a competitive edge. All our products are manufactured in the EU, and our team is ready to provide expert support—from selecting the right technology to comprehensive after-sales service.

Drinking Water

Advanced Lifetech technologies, such as ozone systems and advanced oxidation processes (AOP), are used for drinking water treatment. The combination of ozone and UV radiation generates hydroxyl radicals with an exceptionally high oxidation potential, enabling rapid and effective disinfection.

Find out moreWastewater

In wastewater treatment plants (WWTP), contaminated water from households, municipalities, and some industrial facilities is treated to a quality that allows its safe discharge into the environment.

Find out moreIndustry

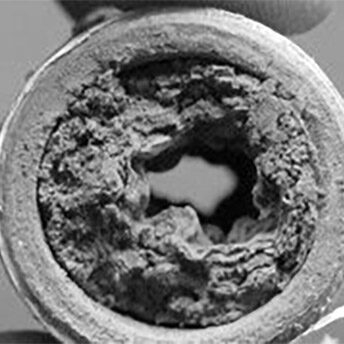

Industrial wastewater contains specific pollutants, including heavy metals, petroleum products, chemicals, and biological contaminants.

Find out moreDisinfection of Cooling Emulsions and Cutting Fluids

Cooling emulsions and cutting fluids are essential in industrial production for cooling, lubrication, and extending the lifespan of machinery. However, prolonged use makes these fluids susceptible to contamination by microorganisms such as bacteria, fungi, and yeasts, leading to reduced efficiency, unpleasant odors, and potential health risks for employees.

Find out moreFood & Beverage

In the food industry, water quality is crucial to ensure food safety, hygiene, and compliance with stringent regulatory requirements. Lifetech provides advanced water disinfection technologies that meet demanding standards while promoting sustainable and cost-effective operations.

Find out moreAquaculture

In aquaculture, maintaining optimal water quality is critical for the health and growth of aquatic organisms, as well as for ensuring efficient and sustainable production.

Find out moreAir Disinfection

Lifetech, through its TriUV product line, offers advanced air disinfection technologies utilizing germicidal UV-C radiation. This technology effectively eliminates bacteria, viruses, and other microorganisms, ensuring a clean and safe environment.

Find out moreLifetech Industry – Solving Your Challenges with Eco-Friendly Solutions

Trust Lifetech's technologies and solutions for industry. With over 30 years of experience in science and industrial applications, we deliver expertise you can rely on.