LifeOX® technology provides the highest possible oxidation potential within AOP

LifeOX® technology provides the highest possible oxidation potential within AOP

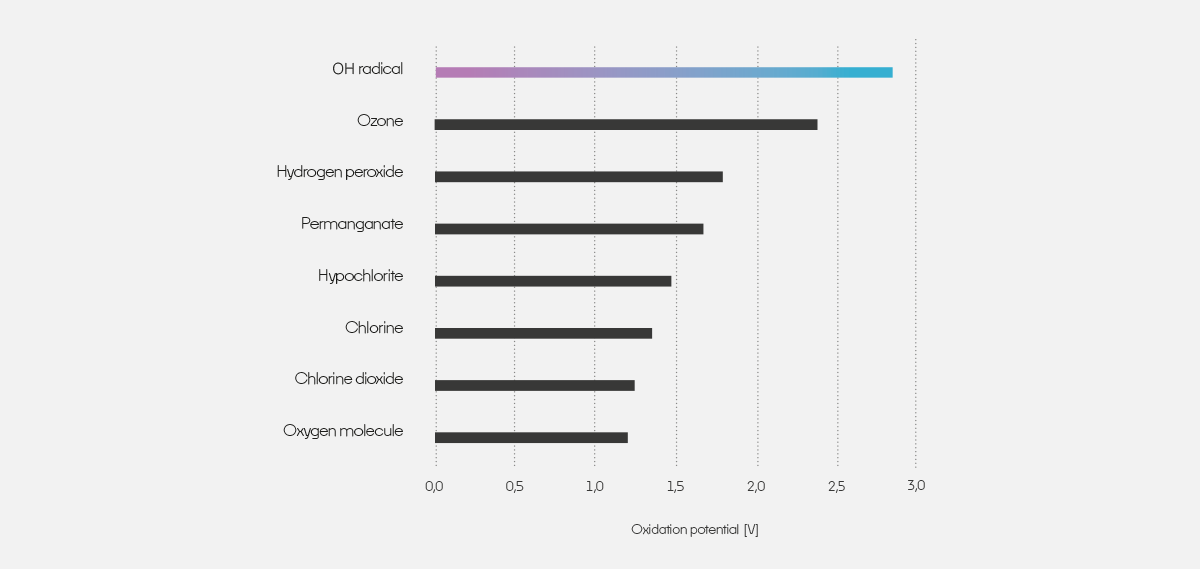

The advanced oxidation process is based on the formation of OH- radicals in water. These OH- radicals have a significantly higher oxidation potential compared to other water treatment oxidants, as they react at least one million times faster than ozone. This means that OH- radicals (i.e., AOP technology) are able to oxidise particles in water much faster and more efficiently. The higher the oxidation potential, the more effective the water disinfection and purification.

The lifetime of OH- radicals is extremely short; the entire water purification process takes place inside the UV reactor within milliseconds. The treated water exiting the reactor does not contain any OH- radicals. The traditional use of ozone or UV technology alone does not guarantee the micropollutants being completely eliminated from treated water. The AOP (Advanced Oxidation Process) is ideal for removing such micropollutants.

Use

Trichloramine poses health risks and damages pool halls, especially in poorly ventilated spaces. LifeOX® M technology uses advanced oxidation with ozone and UV to eliminate harmful compounds, reduce chloramine, and improve water quality. Its modular design ensures quick installation, efficient operation, and a rapid return on investment.

1. Pool waters

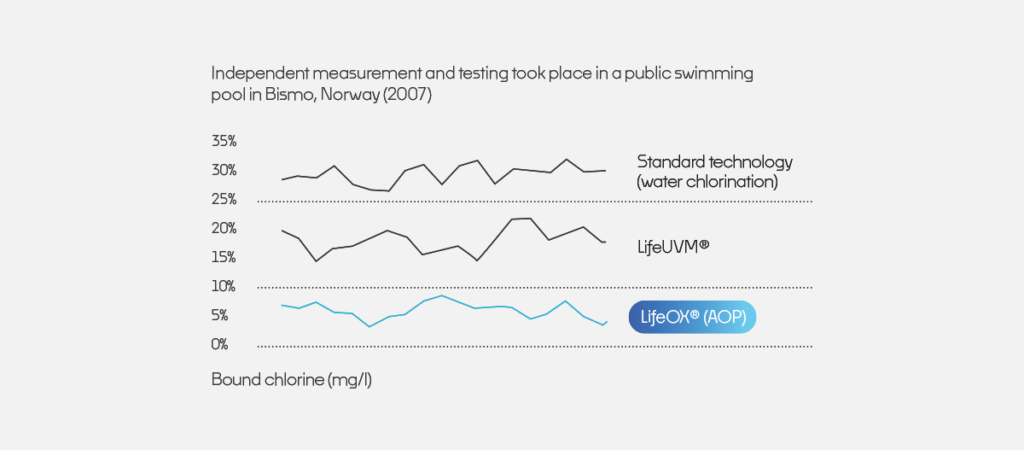

The above-mentioned micropollutants negatively affect human health. For example, trichloramine (a component of bound chlorine) is responsible for eye redness, breathing difficulties, skin drying and irritation, swimmers’ asthma, typical pool odour and even corrosion of pool halls. In general, there is a higher risk in indoor and poorly ventilated areas where trichloramine can be better concentrated. For example, there is up to 3 times more trichloramine in whirlpools than in infant pools. Bound chlorine is also strictly controlled in public pools and is subject to regulation to its maximum con-tent in water in many countries.

The LifeOX® M system is modular, suitable for any pool size. Any water flow rate can be treated by connecting several units in parallel (flow rate 10–250 m3/h). LifeOX®-M installation is extremely quick and easy. Just connect the piping system to the input and output of the unit, bring the electrical power cable and an external signal to turn the unit on and off. The size of the largest LifeOX®-M250 unit is just: width 1500 x depth 1300 x height 1985 mm. The typical return on investment in LifeOX®-M ranges from 8 months to 16 months. Such a fast return on investment is due to reduced consumption of fresh water and chemicals. Thanks to the healthy atmosphere around the pool, the number of visitors to the entire complex will also increase.

2. Wastewater

The technology can also be used for Wastewater that is increasingly polluted with organic substances. Advanced oxidation (AOP) technologies have been shown to be the most effective to remove toxic and persistent compounds such as: carbamazepine, ibuprofen, hormones, geosmin, mib (2-methylisoborneol), 1,4-dioxane, mtbe (methyl tertiary-butyl ether), ndma (N-methyl-D-aspartic acid), atrazine, diuron, diclofenac, etc.

LifeOX® technology

LifeOX® technology is based on the optimised synergy between two proven water treatment technologies: ozone and (low- or medium-pressure) UV system. It does not use hydrogen peroxide, as is the case with standard AOP systems. By incorporating this technology into the LifeOX® M, LIFETECH offers the most efficient and compact system for reducing concentrations of mo-, di-, trichloramine, destroying bacteria, viruses and microorganisms in pool water. The technology breaks down these substances and oxidises organic substances (sweat, urine) contained in pool water, therefore preventing the formation of chloramines (a common process in water chlorination).

Practical functioning in the pool

- Part of the treated water is sucked in by a booster pump (3) which increases the water pressure before entering the injector (4).

- The injector draws gaseous ozone into the treated water, which was generated in the ozone generator (2) from either dry air or oxygen (1 – air dryer or oxygen concentrator).

- Ozone dissolves in water. The reaction / degassing tank serves to achieve a better ozone transfer into the water.

- A small part of the undissolved gaseous ozone is discharged to the residual ozone destructor, where the ozone is decomposed back into oxygen.

- Water with dissolved ozone comes out of the reaction/degassing tank and is then mixed with the main water flow. Now all treated water contains dissolved ozone.

- This ozonised water enters the medium-pressure UVM reactor where OH- radicals are formed in the water as a result of UV irradiation. The oxidation potential of OH- radicals is higher than that of ozone and the oxidation processes take place within several milliseconds. Therefore, all water treatment takes place in the UV reactor space.

It might interest you

Why is Lifetech’s unique technology LifeOX® M the best available technology for pool treatment

Technology

Swimming pools and their health risks: what is not talked about and how to prevent the risks

Healthy pool

LifeAGE® technology sharply reduces the operating costs of medium-pressure UV systems

Technology