LIFETECH has more than 35 years of experience in the development of ozone, UV and AOP (Advanced Oxidation

Process) technologies. It produces ozone generators ranging from the smallest producing only a few mg O3/h

to the largest producing kg O3/h. It also produces both low-pressure and medium-pressure UV systems. AOP

systems manufactured by LIFETECH utilize all combinations of ozone, hydrogen peroxide, low-pressure and

medium-pressure UV systems.

LIFETECH is therefore not bound by any technical limitations in the design of optimal technology, since it

produces all the necessary equipment and technology. LIFETECH always presenting the Best Available

Technology (BAT) to achieve the best water treatment with minimum consumption of fresh water, minimal

power consumption and the fastest possible return on your investment. Achieved water quality ensures a very

pleasant environment around the pool, without the typical pool odour. Swimming is also suitable for toddlers

and asthmatics.

LIFETECH develops, manufactures and implements ozone, UV and AOP technologies for treatment not only of

pool water but also of drinking, waste and industrial water. It has implemented many municipal drinking water

treatment plants. Its clients include internationally renowned companies such as Veolia, Wabag or Culligan.

LIFETECH has developed a unique AOP technology for the removal of dioxins from wastewater for the project

“Decontamination of dioxins in Spolana”, under the umbrella of the English company TCSR and the French

company Suez Environmental. It also developed AOP technology to remove pesticides from drinking water for

Veolia. AOP technology has also been developed for the treatment of recycled water in the wool laundry of the

international company Modiano Group. Based on this experience with outstanding AOP technology for drinking

and waste water treatment, LIFETECH has begun to develop AOP technology optimized for pool water

treatment. Around 2000, the most efficient water treatment technology was described in detail in the German

standard for swimming pools DIN 19 643. As specialists in ozone technology, however, we realized that this

technology does not use optimally generated ozone, only to 50%. In addition, this ozone technology (air dryer

or oxygen generator, ozone generator, auxiliary pump with injector, reaction/degassing tank with ozone

destructor in off-gas, activated carbon filter) occupies a large space in the engine room.

Our first AOP technology, optimized for pool water treatment, is called Combi Ozone / UV and uses ozone and

low pressure UVL systems to produce OH-radicals. Ozone is generated from dry air or dry oxygen to ensure

stable ozone production independent of ambient air humidity. We have been using AOP Combi Ozone / UV

technology for pool water treatment since 2005.

In another development AOP technology we used our technological advantage from the development of

medium-UVM systems. One of the great advantages of a medium pressure UVM system is that it removes the

most harmful substance Trichloramine from the water, unlike low pressure UV systems. This Trichloramine

causes asthma, burning eyes, corrosion and typical pool odour. This results in LifeOX® M equipment – an even

more efficient and compact AOP technology than Combi Ozone/UV for pool, drinking and waste water

treatment.

The uniqueness of LifeOX® M technology has to be seen in the fact that, after installing the technology on a

public aqua park, its attendance has increased from 100,000 people a year to three times, ie to 300,000 people

a year. Moreover, asthmatics and toddlers could finally visit the aquapark. The reason for this radical increase

in interest was to achieve not only exceptional water quality, but also a healthy and pleasant environment in

the aquapark. The return on investment in this unique technology was only eight months. Operators of other

public water parks and private pools have very similar experiences. In many cases, pool halls were corroded

before installing LifeOX® M technology. After the installation of our technology, this serious problem has been

eliminated and they are no longer in danger of collapsing due to corrosion. Sports divers have also learned

LifeOX® M technology. The transparency of the water increased. LifeOX® M technology has solved even heavily

loaded pools – whirlpools and toddler swimming pools. Without this technology, the values of bound chlorine

were around 1.6ppm, which exceeded several times the hygienic limit of 0.2-0.3 ppm. After installing LifeOX® M

the value of bound chlorine dropped below 0.1ppm.

LIFETECH is proud to announce that its LifeOX®-M technology has been selected as the best technology present

in the international design competition for water treatment technology for Russia’s largest and most prestigious

aquapark, the Luzhniki Olympic Center. There are 11 separate swimming pool water treatment circuits in this

aquapark. All pool water is treated with LifeOX M technology. The total water flow treated with LifeOX® M

technology is around 4000 m3/h.

To make the AOP process using ozone as efficient as possible, the following conditions must be respected.

a) Ozone shall be generated from dry air with as little water vapour content as possible. For this reason,

the ozone generator must be equipped with an air dryer or oxygen concentrator. Thereafter, ozone

production is maximum and the same throughout the operation. In addition, the discharge element of

the ozone generator is not destroyed and the discharge element does not need to be replaced. If ozone

is produced from ambient air, then ozone production is highly dependent on the water vapour content

of the ambient air, and production may drop to zero. Instead of ozone generation, nitric acid is

generated, the discharge element is destroyed and this discharge element needs to be changed

periodically.

b) In order to make maximum use of the generated ozone, it should be dissolved into the treated water as

effectively as possible before the dissolved ozone water reaches the UV reactor. This requires an injector

which adds ozone to the treated water and a reaction / degassing tank. This ensures maximum transfer

of ozone into water and at the same time serves to remove undissolved ozone into the ozone destructor

in the off-gas to prevent ozone from entering the environment.

c) If there is no reaction/degassing tank in the technology, this may result in a large noise in the piping

system due to air bubbles in the water. These bubbles reach the pool where swimmers swim. There may

be ozone in the bubbles. This ozone then stays above the surface of the water, causing an unpleasant

odour, irritating the eyes and nose. This is unacceptable from a health point of view.

d) If the reaction/degassing tank is not located upstream of the UV system, then ozone is not sufficiently

dissolved in the treated water. Moreover, the ozone present in the bubbles is decomposed by UV

radiation and is therefore not used for the treatment of pool water.

e) Low pressure UV systems in AOP technologies are used as standard. However, medium pressure UV

systems are preferred because medium pressure UV systems break down the harmful Trichloramines.

Low pressure UV systems do not break down Trichloramines.

f) In order to achieve the healthiest water and the highest quality swimming pool environment, it is

necessary to treat all circulating water.

Only AOP technology incorporating all of the above principles can guarantee you the highest quality water, no

pool odour, no burning eyes, no red eyes, no corrosion, the ability to keep free chlorine at minimum levels

around 0.3ppm, bathing for toddlers and asthmatics.

OVERVIEW OF AOP TECHNOLOGIES

LOW COST LOW DOSE AOP PROCESS – OZONE GENERATION USING LOW-PRESSURE UV LAMP WITHOUT AN

AIR DRYER, WITHOUT REACTION/DEGASSING TANK – eg.Hayward Hydrorite UVO3

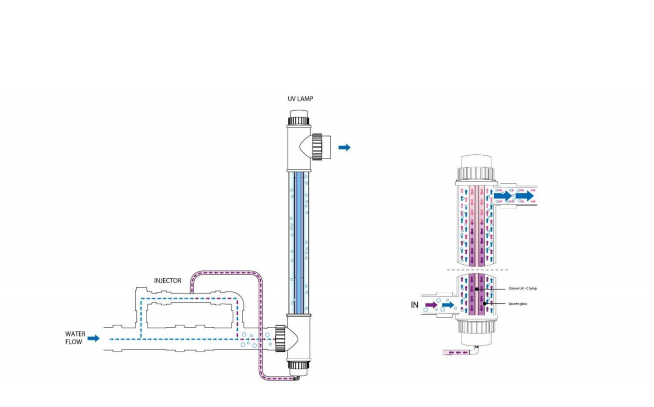

Ozone is generated in the air by UV radiation in the space between the UV discharge lamp and its quartz shell.

The amount of ozone generated depends on the humidity of the air from which the air is drawn into the UV

lamp. From there, ozone is sucked into the water using an injector. Water with ozone bubbles passes around

the UV lamp, where a partial AOP process occurs. Due to the bubbles in the water, not all generated ozone is

used in the AOP process. Bubbles pass further into the piping system and may cause noise. Bubbles also enter

the pool. If they contain ozone residues, they create an unpleasant odour above the surface and the

environment can be hazardous to health.

LOW COST LOW DOSE AOP PROCESS – OZONE GENERATION USING AN OZONE GENERATOR WITHOUT AN

AIR DRYER, WITHOUT REACTION/DEGASSING TANK– eg. Del AOP

Ozone is generated in the air by UV radiation in the space between the UV discharge lamp and its quartz shell.

The amount of ozone generated depends on the humidity of the air from which the air is drawn into the UV

lamp. From there, ozone is sucked into the water using an injector. Water with ozone bubbles passes around

the UV lamp, where a partial AOP process occurs. Due to the bubbles in the water, not all generated ozone is

used in the AOP process. Bubbles pass further into the piping system and may cause noise. Bubbles also enter

the pool. If they contain ozone residues, they create an unpleasant odour above the surface and the

environment can be hazardous to health.

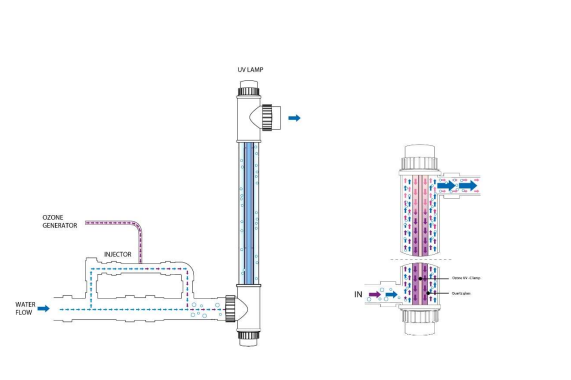

LOW COST LOW DOSE AOP PROCESS – OZONE GENERATION USING AN OZONE GENERATOR WITHOUT AN

AIR DRYER, WITHOUT REACTION/DEGASSING TANK– eg. Del AOP

Ozone is generated in the air in the ozone generator. The ambient air is sucked into the ozone generator by

the vacuum generated by the injector. The amount of ozone generated depends on the ambient air humidity

as there is no air dryer installed. The generated ozone is sucked into the water using an injector. Water with

ozone bubbles passes around the low pressure UV lamp, where a partial AOP process occurs. Due to the

bubbles in the water, not all generated ozone is used in the AOP process. Bubbles pass further into the piping

system and may cause noise. Bubbles also enter the pool. If they contain ozone residues, they create an

unpleasant odour above the surface and the environment can be hazardous to health.

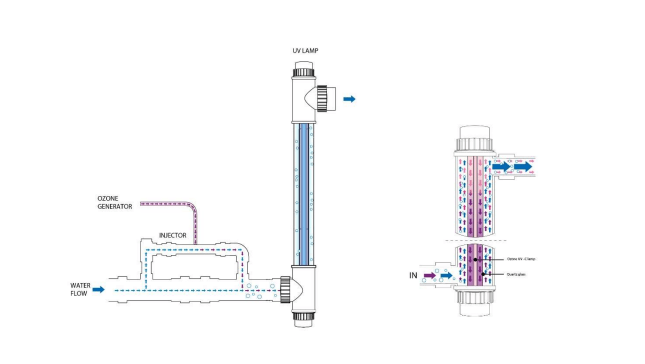

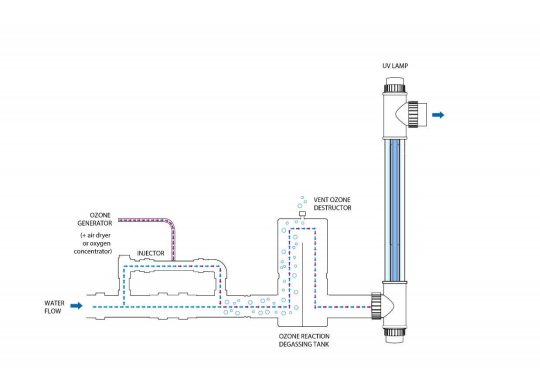

Combi Ozone/UV – AOP PROCESS BY LIFETECH WITH LOW-PRESSURE UV SYSTEM

Ozone is generated here from dry air thanks to the installation of an air dryer or oxygen concentrator. Part of

the water from the main flow is sucked by the booster pump into the injector where the water is mixed with

ozone. In the reaction and degassing tank, ozone is dissolved in water and the undissolved ozone gas is

discharged to the ozone destructor in the off-gas. From the reaction tank water with dissolved ozone is

released, without bubbles. Ozonized water enters a stainless steel UV reactor with a low pressure UV lamp,

where the AOP process occurs. Water without dissolved ozone is leaving the UV reactor. In the Combi

Ozone/UV, water is treated with three technologies: ozone, low pressure UV systems and the AOP process.

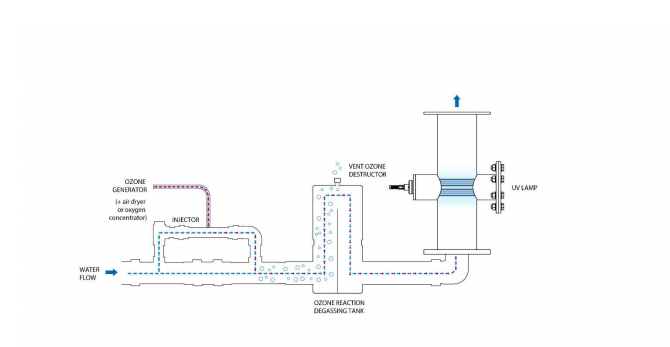

LifeOX® M – UNIQUE AOP PROCESS DEVELOPED BY LIFETECH, BEST AVAILABLE AOP TECHNOLOGY FOR POOL

WATER TREATMENT

Ozone is generated here from dry air thanks to the installation of an air dryer or oxygen concentrator. Part of

the water from the main flow is sucked by the booster pump into the injector where the water is mixed with

ozone. In the reaction and degassing tank, ozone is dissolved in water and the undissolved ozone gas is

discharged to the ozone destructor in the off-gas. From the reaction tank water with dissolved ozone is released,

without bubbles. Ozonized water enters a stainless steel UV reactor with a medium pressure UV lamp, where

the AOP process occurs. Water without dissolved ozone is leaving the UV reactor. In LifeOX® M, water is treated

with three technologies: ozone, medium pressure UV systems and the AOP process.

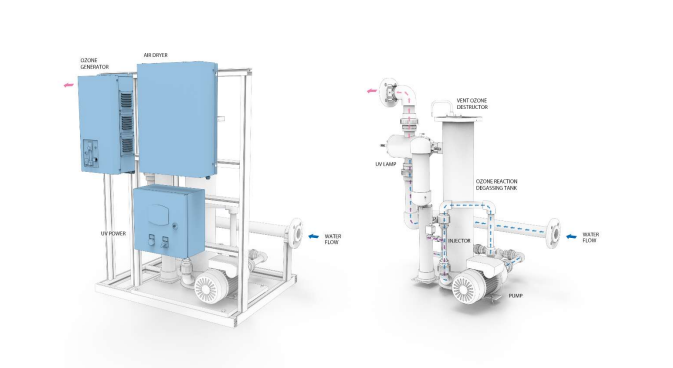

LifeOX® M MODELS FOR WATER FLOWS UP TO 10 and 20 m3/h

Ozone is generated from dry air due to the installation of an air dryer. Part of the water from the main flow is

sucked by the booster pump into the injector where the water is mixed with ozone. In the reaction and

degassing tank, ozone is dissolved in water and the undissolved ozone gas is discharged to the ozone

destructor in the off-gas. From the reaction tank water with dissolved ozone is released, without bubbles.

Ozonized water returns to the main stream and thus all treated water contains dissolved ozone. Ozonized

water enters a stainless steel UV reactor with a medium pressure UV lamp, where the AOP process occurs.

Water without dissolved ozone is leaving the UV reactor. In LifeOX® M, water is treated with three

technologies: ozone, medium pressure UV systems and the AOP process.

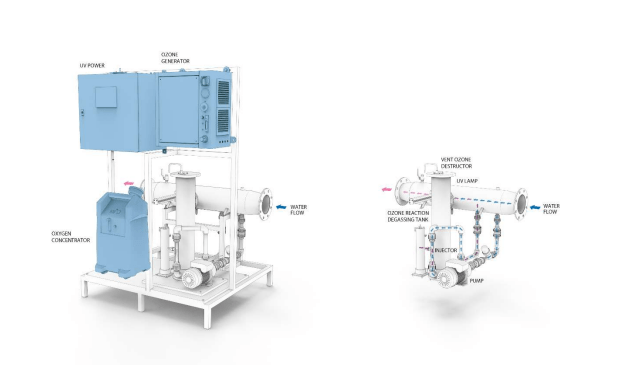

LifeOX® M MODELS FOR WATER FLOWS UP TO 90, 140 and 250 m3/h

Ozone is generated here from dry oxygen thanks to the installed oxygen concentrator. Part of the water from

the main flow is sucked by the booster pump into the injector where the water is mixed with ozone. In the

reaction and degassing tank, ozone is dissolved in water and the undissolved ozone gas is discharged to the

ozone destructor in the off-gas. From the reaction tank, water with dissolved ozone is released, without

bubbles. Ozonized water returns to the main stream and thus all treated water contains dissolved ozone.

Ozonized water enters a stainless steel UV reactor with a medium pressure UV lamp, where the AOP process

occurs. Water without dissolved ozone is leaving the UV reactor. In LifeOX® M, water is treated with three

technologies: ozone, medium pressure UV systems and the AOP process.

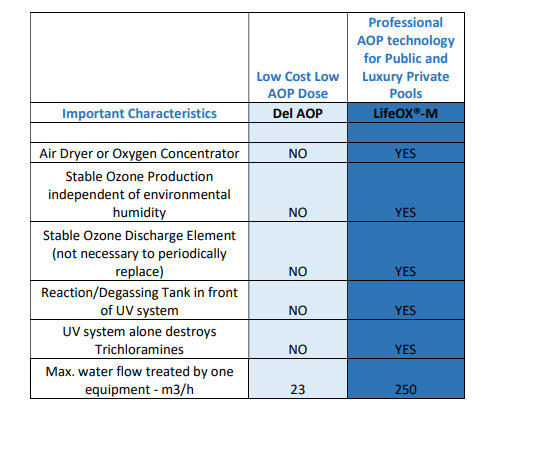

CLEAR COMPARISON OF LOW DOSE AOP DEVICES AND

PROFESSIONAL DEVICES WITH THE MOST EFFICIENT AOP