There is a fundamental difference between whether a given device has been certified for disinfection efficiency by an independent accredited lab-oratory or only the manufacturer and refers to generally accepted statistics concerning the effectiveness of UV radiation. The germicidal properties of UV radiation have been known for more than 100 years, but this does not guarantee that the disinfection equipment has the effectiveness referred to by the manufacturer. Three basic methods are used to determine the disinfection efficiency of UV radiation.

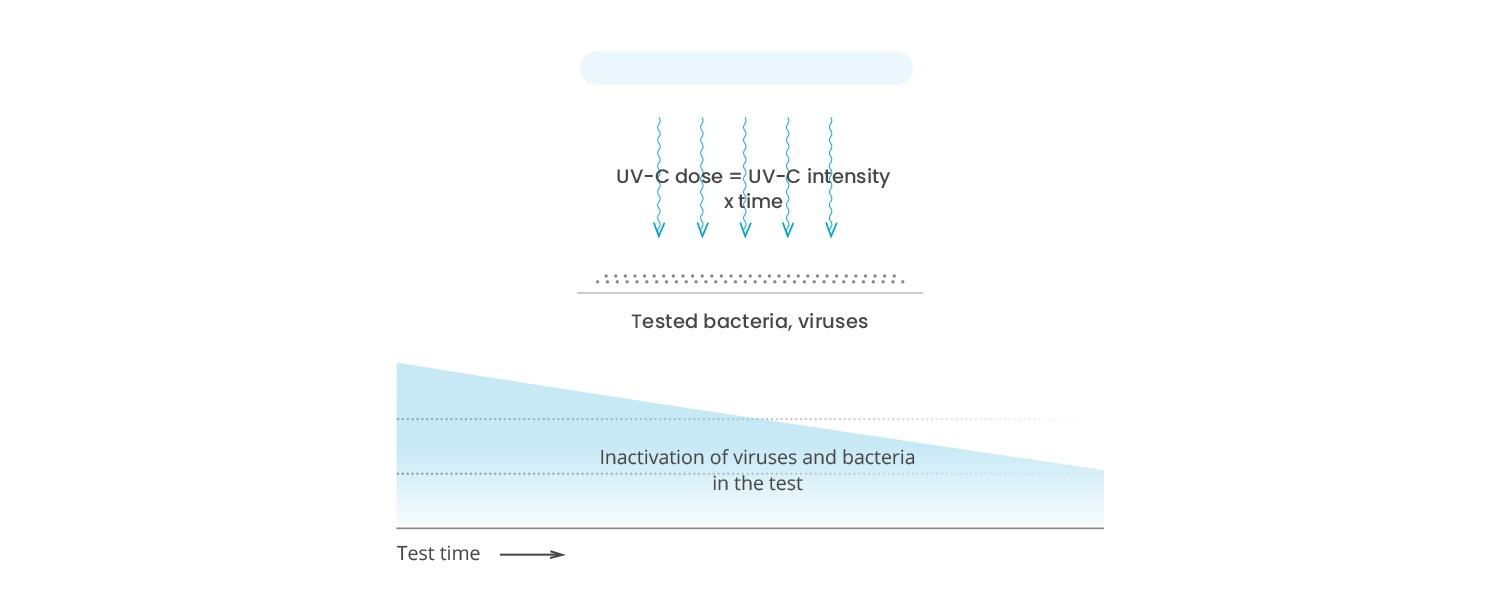

The UV lamp is placed at a certain distance above a substrate, which is con-taminated in a defined way with a given type of bacteria, viruses or fungi. The pad is irradiated for a period of time and then the number of surviving bacteria or viruses is determined. This determines the required dose of UV radiation (product of UV intensity mW/cm2 and irradiation time sec) for a given degree of disinfection and for a given type of bacteria, etc. This is a basic test of UV effects, but says nothing about a specific disinfection device using UV radiation.

Manufacturers of air disinfection units, which state the disinfection efficien-cy (preferably 99.999%) of their equipment on the basis of this measure-ment, deliberately deceive the public. This method of measurement says nothing about the disinfection efficiency of their equipment, which can easily be close to zero.

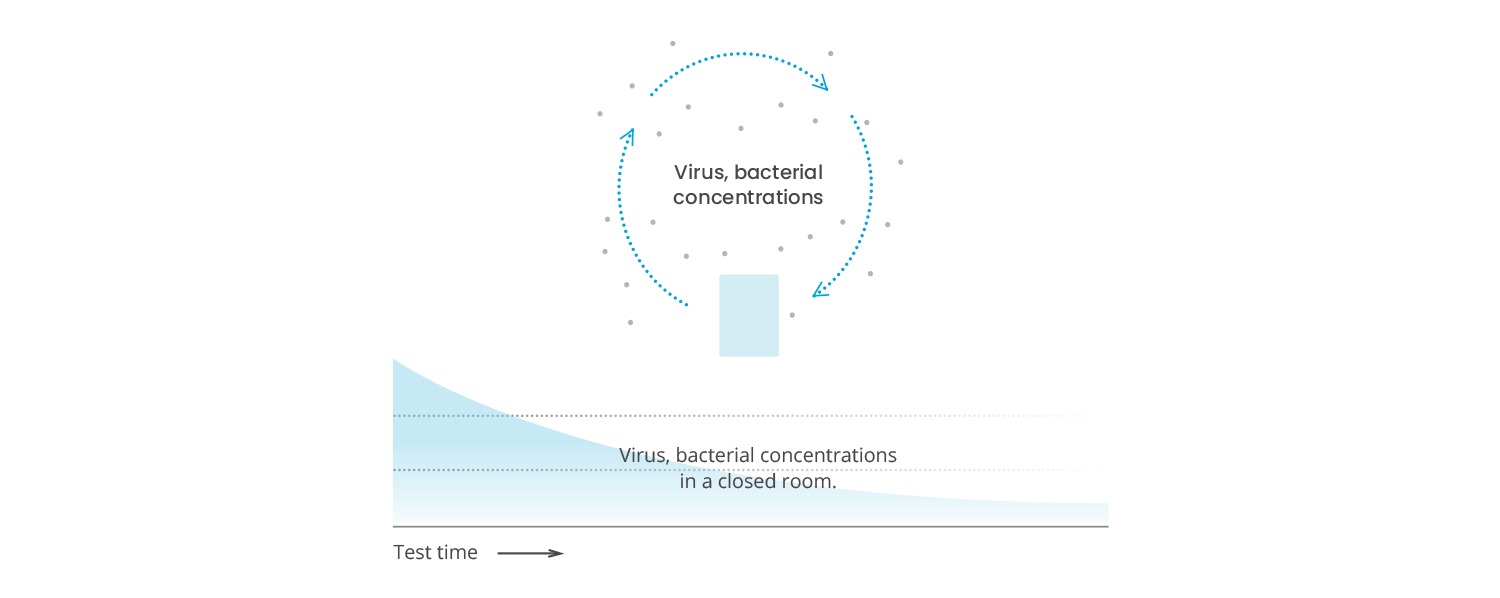

he measured disinfection unit is placed in an enclosed space. For exam-ple, a given type of virus is scattered throughout the space. Subsequently, a part of the contaminated air is sucked from the space through the filter.

The number of viruses captured on the filter determines the concentration of viruses in the test chamber. The disinfection unit is now switched on and the virus concentration is determined in the same way as a function of time. In this way, the disinfection efficiency of the device depends on the time for the virus being tested.

Manufacturers subsequently present this method of measuring disinfec-tion efficiency, for example, as follows. “Independent measurements have shown that the disinfection efficiency of our equipment is 99.99%.”

Such a statement is again deliberately misleading and confusing, avoiding the full truth about the device. These manufacturers must also provide you with the following information: During what time period was the given efficiency achieved, what was the volume of the test chamber and what was the actual air flow through the given device?

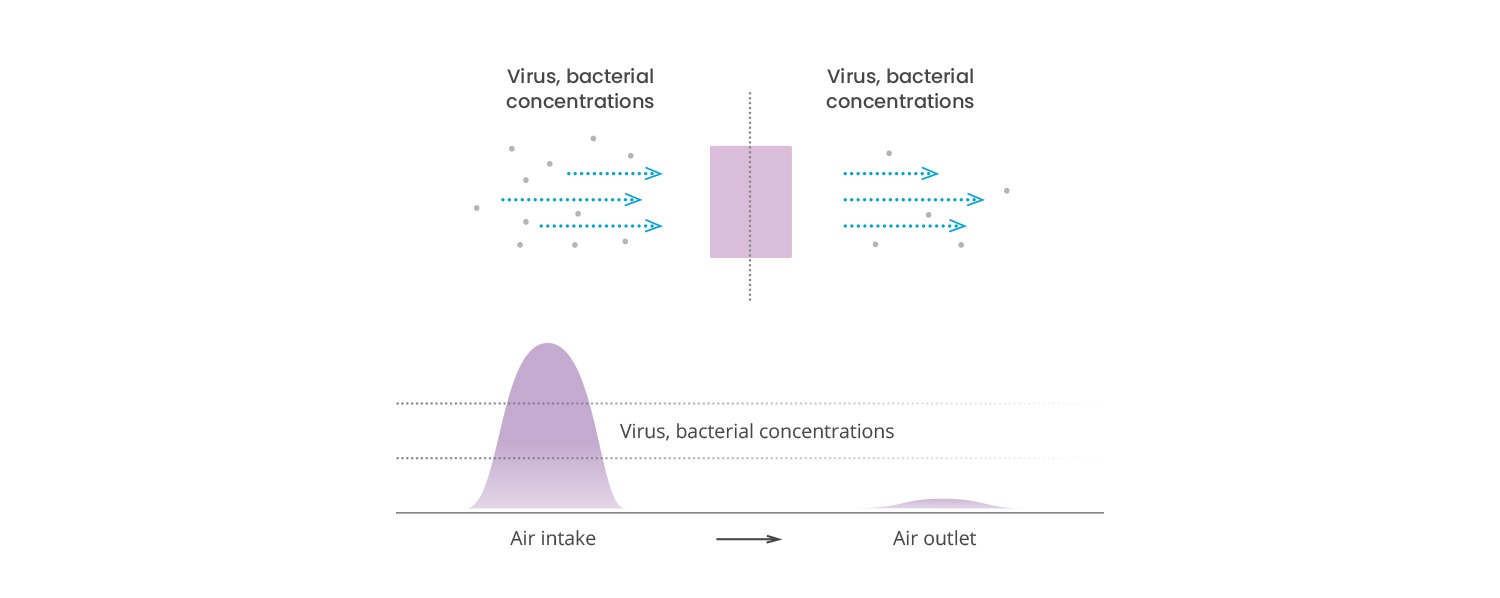

The tested disinfection unit is placed in an enclosed space to prevent biological contamination of the surrounding area. A suspension of tested viruses or bacteria is sprayed into the air entering the disinfection unit. At the outlet of the disinfection unit, samples are taken for a certain time us-ing a membrane filter. The membranes used are then dissolved in a buffer and the amount of virus or bacteria collected is determined by serial dilu-tion and subsequent agar assay. To determine the degree of inactivation, an experiment is performed with and without active UV-C. This method of measuring the degree of disinfection of a given device is unambiguous and can be interpreted in only one way. It does not allow the various tactical loopholes to improve the impression of the device, as is possible with the previous method of testing.

Using a specific example, we will show how confusing information about the disinfection efficiency of a unit measured in an enclosed space can be if all the details of the experiment are not given in one place. With plasma disinfection, you can read that 99.9909% inactivation is achieved in 15 min-utes. At first glance, the device has amassing efficiency. However, the view of the efficiency and consumption of this device will change radically if we put together all the necessary data. The power consumption of the device at a maximum air flow of 906 m3 / h is 331W. The most important finding is that the disinfection efficiency was tested in an enclosed space with a vol-ume of only 16 m3. Thus, all the air in the test chamber passed through the plasma device 14 times in 15 minutes. Based on these values, the efficiency of the device can be determined in a single pass.

In order to achieve an overall efficiency of 99.9909% for the plasma disinfection unit in 15 minutes, then the efficiency of the device in a single pass is only about 50%. From this particular example, it is clear why it is so important to test the disinfection efficiencies of a device in a single pass through the device. Based on these data, a qualified decision on the selection of the disinfection unit can only be made and it does not depend on whether the disinfection takes place by means of UV radiation, plasma discharge or by means of photocatalysts.

A more detailed analysis of the disinfection units can be found in the article “Comparison of disinfection units … critical review”.